Click here to read this mailing online.

Here are the latest updates for jorgeus.george@gmail.com

"Next Big Future" - 8 new articles

"Next Big Future" - 8 new articles

- Superconducting Bi-2212 wire that has five times higher current and will enable superconducting magnets with over 30 Tesla

- “Yolk-shell” design stores five times more energy in the sulfur cathode of a rechargeable lithium-ion battery than commercial batteries

- Laser based generation of high energy neutrons

- Printing human embryonic stem cells

- Cable companies make 97% margin on internet services and have no incentive to offer gigabit internet

- An economical way to convert carbon dioxide into calcium carbonate

- Self-assembled quantum dots in a nanowire system for quantum photonics

- More efficient computer displays to enhanced biomedical testing from better quantum dots

- More Recent Articles

- Search Next Big Future

- Prior Mailing Archive

Superconducting Bi-2212 wire that has five times higher current and will enable superconducting magnets with over 30 TeslaA group of scientists has discovered how to make better wires using a promising material known as Bi-2212. With this discovery comes the possibility of creating magnetic fields in excess of 30 Tesla, three to four times higher than those generated by present accelerator magnet technology.

Bi-2212 stands out as the only HTS (high temperaure superconductor) that can be fabricated as a round wire. This makes Bi-2212 a perfect candidate for winding cables and coils without significantly changing present magnet technology.

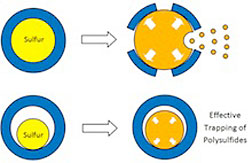

Researchers have developed a technique that prevents bubble formation almost entirely by performing the melting and re-solidification of materials under high external gas pressure. The group observed five times higher current in a long wire sample made by the new method compared to an identical sample made by the standard recipe. Importantly, the electrical currents in the improved Bi-2212 wires were two times larger than the usual benchmarks used for the development of superconducting magnet coils. This breakthrough signifies the birth of a new high-performance, very-high-field magnet conductor. Shen and his collaborators are optimistic that they now have the recipe for a new class of superconducting magnets that could help unlock information about chemical and biological processes, create new materials and reveal the fundamental processes of the universe. Arxiv - Processing long-length Ag-sheathed Bi2Sr2CaCu2Ox wires for high critical current density: internal gases and creep of Ag at high temperatures (22 pages) Read more » “Yolk-shell” design stores five times more energy in the sulfur cathode of a rechargeable lithium-ion battery than commercial batteriesScientists from DOE's SLAC National Accelerator Laboratory and Stanford University have set a world record for energy storage, using a clever “yolk-shell” design to store five times more energy in the sulfur cathode of a rechargeable lithium-ion battery than is possible with today’s commercial technology. The cathode also maintained a high level of performance after 1,000 charge/discharge cycles, paving the way for new generations of lighter, longer-lasting batteries for use in portable electronics and electric vehicles.

Cui’s innovation is a cathode made of nanoparticles, each a tiny sulfur nugget surrounded by a hard shell of porous titanium dioxide, like an egg yolk in an eggshell. Between the yolk and shell, where the egg white would be, is an empty space into which the sulfur can expand. During discharging, lithium ions pass through the shell and bind to the sulfur, which expands to fill the void but not so much as to break the shell. The shell, meanwhile, protects the sulfur-lithium intermediate compound from electrolyte solvent that would dissolve it.

Previous attempts to make sulfur cathodes using bare sulfur or simply coated particles could not prevent the dramatic reduction of energy-storage capacity as the lithium-sulfur intermediate compounds (polysulfides) created during charging broke free and dissolved away. (Credit: Zhi Wei She, Stanford University) Read more » Laser based generation of high energy neutronsA new compact high-flux source of energetic neutrons has been built by physicists in Germany and the US. The new laser-based device has the potential to be cheaper and more convenient than the large neutron facilities currently used by physicists and other scientists. The inventors say the source could be housed in university laboratories and might also be used to identify illicit nuclear material.

Neutrons are a valuable tool for scientists in many fields, allowing them to probe the structure and dynamics of a range of materials. Today, the main drawback of neutron science is that intense beams of neutrons must be produced in either nuclear reactors or dedicated accelerator facilities – making a laser-based table-top source very attractive.

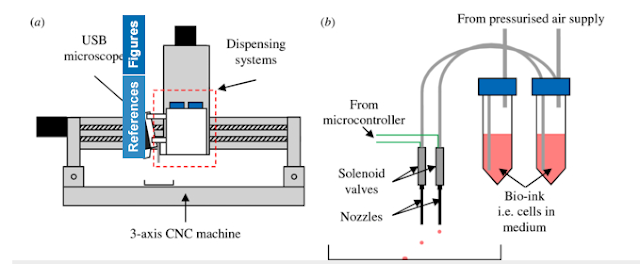

Read more » Printing human embryonic stem cellsIn recent years, the use of a simple inkjet technology for cell printing has triggered tremendous interest and established the field of biofabrication. A key challenge has been the development of printing processes which are both controllable and less harmful, in order to preserve cell and tissue viability and functions. Here, we report on the development of a valve-based cell printer that has been validated to print highly viable cells in programmable patterns from two different bio-inks with independent control of the volume of each droplet (with a lower limit of 2 nL or fewer than five cells per droplet). Human ESCs were used to make spheroids by overprinting two opposing gradients of bio-ink; one of hESCs in medium and the other of medium alone. The resulting array of uniform sized droplets with a gradient of cell concentrations was inverted to allow cells to aggregate and form spheroids via gravity. The resulting aggregates have controllable and repeatable sizes, and consequently they can be made to order for specific applications. Spheroids with between 5 and 140 dissociated cells resulted in spheroids of 0.25–0.6 mm diameter. This work demonstrates that the valve-based printing process is gentle enough to maintain stem cell viability, accurate enough to produce spheroids of uniform size, and that printed cells maintain their pluripotency. This study includes the first analysis of the response of human embryonic stem cells to the printing process using this valve-based printing setup.

Tests showed that 80-90% of the embryonic stem cells stayed viable. a) Schematic drawing of the cell printer system. (b) Detailed schematic of the two dispensing systems. IOP Science - Development of a valve-based cell printer for the formation of human embryonic stem cell spheroid aggregates Read more » Cable companies make 97% margin on internet services and have no incentive to offer gigabit internetThe cable distribution giants like Time Warner Cable and Comcast are already making a 97 percent margin on their “almost comically profitable” Internet services, according to Craig Moffet, an analyst at the Wall Street firm Bernstein Research. As Levin points out, “If you are making that kind of margin, it’s hard to improve it.” And most Americans have no choice but to deal with their local cable company.

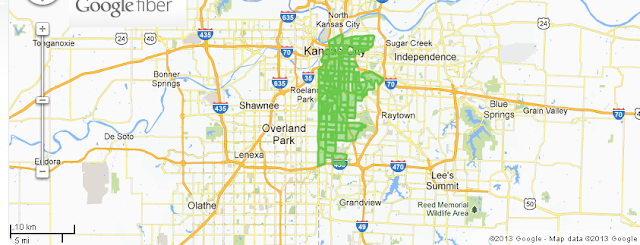

Google fiber is mostly deploying in February and April of this year in Kansas. There are some areas that already have installation in progress. Confirmation of Lazy Money Grubbing Evil While Verizon operates the fiber network serving the largest number of home subscribers in the nation, the company is backing off from installing additional U.S. fiber connectivity. The company’s fiber service, called FiOS, offers basic service starting at 15 megabits per second (which can be upgraded in some areas to as much as 300 megabits per second). Verizon CFO Fran Shammo said in a conference call last fall that there are no plans to expand FiOS beyond those areas. “At this point we have to capitalize on what we have invested,” he said. The basic goal is to sign up more people in the existing service areas, which adds the most revenue without increasing capital costs. The other cable and telecom companies are focused on capitalizing on existing cable infrastructure, not emulating Google Fiber by building out fiber connections to homes and businesses. In Kansas City, Time Warner Cable in late January (likely in response to Google Fiber’s presence) boosted speeds and lowered prices, offering download speeds of 100 megabits per second for $75 a month. For $199 users can get cable bundled with TV and phone service, with two DVR. Google Fiber, Gig.U and some City Gigabit Efforts During an earnings call earlier this month, Google CFO Patrick Pichette said the company plans to finish building out the whole city, on both the Kansas and Missouri sides of the state line, and added that the effort “is not a hobby: we really think that we should be making good business with this opportunity, and we are going to continue to look at the possibility of expanding.”

Read more » An economical way to convert carbon dioxide into calcium carbonateA chance discovery that sea urchins use Nickel particles to harness carbon dioxide from the sea to grow their exoskeleton could be the key to capturing tonnes of CO2 from the atmosphere.

Experts at Newcastle University, UK, have discovered that in the presence of a Nickel catalyst, CO2 can be converted rapidly and cheaply into the harmless, solid mineral, calcium carbonate. The process developed by the Newcastle team involves passing the waste gas directly from the chimney top, through a water column rich in Nickel nano-particles and recovering the solid calcium carbonate from the bottom. They are looking for business partners to develop their patented process. Read more » Self-assembled quantum dots in a nanowire system for quantum photonicsNature Materials - Quantum dots embedded within nanowires represent one of the most promising technologies for applications in quantum photonics. Whereas the top-down fabrication of such structures remains a technological challenge, their bottom-up fabrication through self-assembly is a potentially more powerful strategy. However, present approaches often yield quantum dots with large optical linewidths, making reproducibility of their physical properties difficult. We present a versatile quantum-dot-in-nanowire system that reproducibly self-assembles in core–shell GaAs/AlGaAs nanowires. The quantum dots form at the apex of a GaAs/AlGaAs interface, are highly stable, and can be positioned with nanometre precision relative to the nanowire centre. Unusually, their emission is blue-shifted relative to the lowest energy continuum states of the GaAs core. Large-scale electronic structure calculations show that the origin of the optical transitions lies in quantum confinement due to Al-rich barriers. By emitting in the red and self-assembling on silicon substrates, these quantum dots could therefore become building blocks for solid-state lighting devices and third-generation solar cells.

HAADF-STEM image of a GaAs nanowire coated with an AlGaAs shell. The formation of finite Al-poor islands is also observed. 14 pages of supplemental material Read more » More efficient computer displays to enhanced biomedical testing from better quantum dotsAn MIT team says that it has succeeded in overcoming all the obstacles to improved quantum dots performance at once, while earlier efforts have only been able to tackle them one or a few at a time. Quantum dots — in this case, a specific type called colloidal quantum dots — are tiny particles of semiconductor material that are so small that their properties differ from those of the bulk material: They are governed in part by the laws of quantum mechanics that describe how atoms and subatomic particles behave. When illuminated with ultraviolet light, the dots fluoresce brightly in a range of colors, determined by the sizes of the particles.

First discovered in the 1980s, these materials have been the focus of intense research because of their potential to provide significant advantages in a wide variety of optical applications, but their actual usage has been limited by several factors. The new process developed by the MIT team produces quantum dots with four important qualities: uniform sizes and shapes; bright emissions, producing close to 100 percent emission efficiency; a very narrow peak of emissions, meaning that the colors emitted by the particles can be precisely controlled; and an elimination of a tendency to blink on and off, which limited the usefulness of earlier quantum-dot applications. Nature Materials - Compact high-quality CdSe–CdS core–shell nanocrystals with narrow emission linewidths and suppressed blinking Read more » More Recent Articles

|